Higher quality process water and a contribution to our sustainability ambition

Coolpack (part of De Ridder BV) from Assendelft has been a specialist manufacturer of cooling products such as gel packs, cooling elements, and cooling plates that keep products at the right temperature during transport and storage for more than 40 years. These are used worldwide in the retail, food, pharmaceutical, and logistics sectors. In addition, Coolpack is increasingly supplying installation-related products with PCM as a solution to the grid congestion challenges we face in the Netherlands. Lex Appel, Technical Manager at Coolpack, talks about their success with Watter in the search for more sustainable and optimized business operations.

Optimization of an already high-quality process

Coolpack uses a lot of process water during the production process. The company operates in accordance with ISO 9001 and ISO 14001 certifications, which guarantee both quality management and environmental management. However, traditional water management methods, such as periodic cleaning and existing techniques such as UV lamps, required considerable attention in terms of using the right (cleaning) agents, were labor-intensive, and consumed a lot of energy. This was at odds with Coolpack's growing sustainability ambitions.

The company sought a future-proof solution: a method that could maintain the already high quality standard with minimal effort and make water management more sustainable. They wanted a greener and more efficient way to guarantee the constant and excellent water quality that is crucial for product stability.

Seeking sustainability without compromise

The objective was clear: robust and chemical-free process water management that maintains minimum product quality and reduces the ecological footprint. During an online search for ‘sustainable process water management’, Lex came across the Watter system.

“On the website, I read that Americol, a company in our region, had already achieved good results with it in terms of quality and sustainability,” says Lex. “That gave me confidence.” After visiting Americol, where they saw the system in action, the decision was quickly made: Coolpack started a five-month trial to test whether the Watter solution could offer the desired sustainability while maintaining high quality standards.

Result: quality that exceeds internal standards even further

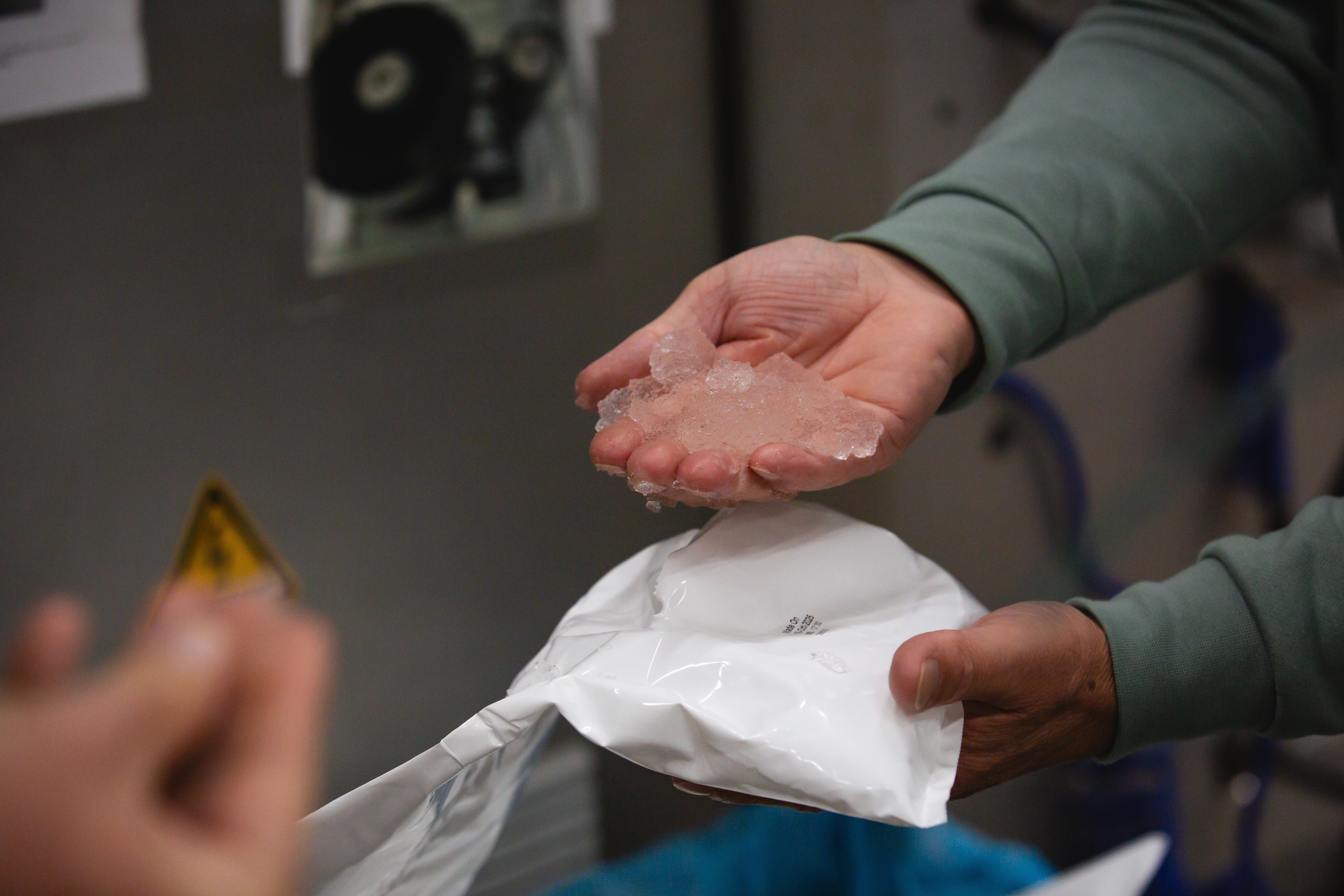

What followed exceeded expectations. The process water remained structurally stable, and the trial proved that Watter was not only a sustainable alternative but also had an unprecedented impact on quality. "The water is crystal clear. The germ counts were already good, but now they are structurally even further below our internal standard. It proves that you can become more sustainable and at the same time raise quality to an even higher level," says Lex with a smile. The system was immediately incorporated into the standard process.

At Coolpack, we have made a significant quality improvement in our production process by adding Watter to our system. This step not only ensures that our products meet the highest standards, but also guarantees that our customers receive the best possible quality. Together, we are building trust and satisfaction.

More stable process and sustainable profit

Since switching to the Watter system, germ counts have remained well below the internal standard, providing an extra margin of safety. The production process is more stable and the necessary cleaning rounds are shorter and much less frequent.

“It brings peace of mind to our process and makes work more enjoyable” says Lex.

In addition to the operational and qualitative gains, the system fits seamlessly within Coolpack's sustainability policy. The improvement in efficiency means less transport, less waste, and less CO₂ emissions. Astrid Oversier, Sustainability Officer at Coolpack, says: “The Watter system shows that sustainability and quality improvement can go hand in hand.”

Discover the possibilities for a trial setup, just like Coolpack

Request more information today!