What is biofilm?

Biofilm forms when microorganisms adhere to surfaces in wet environments and become surrounded by a protective matrix of extracellular polymers. This process occurs in four phases:

- Initial attachment – Free-living (planktonic) microorganisms temporarily contact a surface via weak Van der Waals forces and electrostatic interactions. This phase is reversible.

- rreversible attachment / Microcolony formation – The bacteria produce extracellular polymers (EPS) that strengthen the attachment and begin dividing. This creates microcolonies. Quorum sensing and other forms of communication play a role in this process.

- Maturation I – The biofilm grows in thickness and complexity. Structures such as channels for nutrient transport develop. The biofilm begins to provide protection against antimicrobials and stressors.

- Maturation II – The biofilm reaches full maturity with a complex architecture. Physiological differentiation of cells within the biofilm occurs, depending on the local environment (oxygen, nutrients).

- Dispersion – Cells or cell clusters leave the biofilm, often influenced by internal or external signals. This leads to colonization of new surfaces and the repetition of the cycle.

Biofilm forms a reservoir for pathogenic microorganisms such as Pseudomonas aeruginosa, Escherichia coli, and Legionella pneumophila, which can lead to hygiene problems, blockages, and reduced system efficiency.

Why Traditional Methods Fall Short

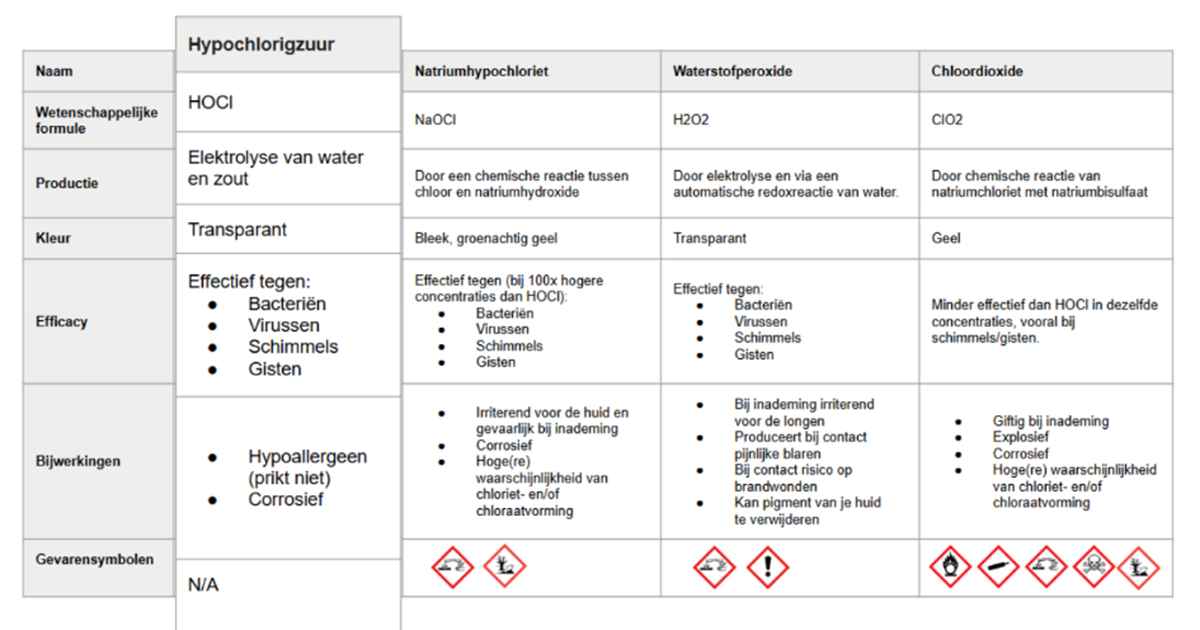

Commonly used disinfectants like sodium hypochlorite or chlorine dioxide require high concentrations and long contact times to effectively combat biofilms. Moreover, they often fail to penetrate the core of the biofilm structure. This is because the extracellular matrix (EPS) of biofilms hinders chemical diffusion, especially for larger or reactive molecules. At the same time, some microorganisms within biofilms can trigger stress responses, such as the formation of persister cells or the secretion of neutralizing enzymes (e.g., catalase in Pseudomonas aeruginosa), which reduce the effectiveness of oxidizing agents (1).

Hypochlorous acid (HOCl) also encounters these barriers, but to a lesser extent. Due to its small, neutrally charged molecular shape, HOCl diffuses through the EPS matrix more effectively than many other disinfectants (2). Furthermore, HOCl has a broad mechanism of action: it oxidizes sulhydryl groups in enzymes, denatures structural proteins, damages lipid membranes, and induces DNA damage. This multi-target approach makes it more difficult for microorganisms to develop targeted defense mechanisms (3).

The solution: the Watter system

The Watter system produces hypochlorous acid (HOCl) on-site at a stable concentration of approximately 250 ppm. Thanks to its electrochemical production method, the product is immediately usable, with high antimicrobial effectiveness at low doses. This system offers an efficient approach to biofilm and microbial contamination, without the disadvantages of conventional chemicals.

HOCl has a broad spectrum of activity and is effective against numerous biofilm-forming microorganisms. The system is used in, among other areas:

- PT2 - Disinfectants and algaecides not used directly on humans or animals. Products for disinfecting surfaces, materials, equipment, and furniture that are not used for direct contact with food or animal feed.

- PT4 - Products for disinfecting equipment, containers, eating and drinking utensils, surfaces, or pipelines for the production, transport, storage, or consumption of food or animal feed (including drinking water) for humans and animals. It is also approved in the Netherlands for the treatment of drinking water for animals (PT5).

- PT5 - Drinking Water. Products for disinfecting drinking water (for humans and animals).

Would you like to learn more about possible applications within your process? Contact us for technical specifications or application advice.

Scientific Evidence

Hypochlorous acid (HOCl) has been proven effective against a broad spectrum of microorganisms, including Gram-negative and Gram-positive bacteria, yeasts, and molds. In industrial environments, the presence of biofilm-forming species such as Listeria monocytogenes, Escherichia coli, Salmonella enterica, Pseudomonas aeruginosa, and Staphylococcus aureus is considered particularly critical. These organisms often form multispecies biofilms that are resistant to cleaning and conventional disinfection.

Biofilms form a protective matrix of extracellular polymers (EPS), in which microorganisms collectively organize. Traditional disinfectants such as sodium hypochlorite (NaOCl), hydrogen peroxide, or quaternary ammonium compounds struggle to fully penetrate this matrix, especially at low concentrations or short contact times. Moreover, they can lead to the development of resistance or material stress with frequent use.

HOCl is distinguished by its small molecular size, neutral charge, and high redox potential, which enables rapid penetration and broad antimicrobial activity, even in biofilm structures. Under controlled conditions, HOCl has been shown to effectively reduce biofilms on stainless steel, even at concentrations around 200–250 ppm and contact times of several minutes [1].

For an analysis of relevant microorganisms within your production environment and the effectiveness of HOCl against them, sector-specific advice from our microbiologists is available.

Extensive practical experience and success in biofilm reduction

In a variety of industrial environments – from process installations to technical infrastructure – the Watter system has been demonstrated in practice to effectively reduce existing biofilms and limit their regrowth. These results have been achieved in systems with varying water quality, temperature fluctuations, and material surfaces.

The system is applied to pipes, storage tanks, humidification systems, CIP systems, and other areas where water and microorganisms interact. By using hypochlorous acid (HOCl) at a stable working concentration, microbial load is targeted, even in complex systems with fluctuating operating loads.

Implementation takes place in consultation with relevant officials such as QA managers, system operators, and technical services. Based on microbiological monitoring and system-specific risk analysis, the application is tailored to local conditions.

Ontdek de bewezen betere optie van Watter.

Do you want to sustainably remove and prevent biofilm?

Watter combineert diepgaande microbiologische kennis met geavanceerde technologie voor een systematische aanpak van biofilm. Door onze praktijkervaring en wetenschappelijke benadering bieden wij een bewezen effectieve oplossing die voldoet aan wettelijke eisen voor PT2, PT4 en PT5.