Legionella pneumophila is a bacteria that can develop in water and cause infectious pneumonia known as legionellosis. The bacteria can be found in water sources such as hot springs, air conditioning systems, water tanks and sprinkler and watering systems.

How does Legionella form in water pipes?

Legionella can develop in water pipes when they come in contact with water with a temperature between 20-45°C. The bacteria multiply rapidly at these temperatures, especially if there is not sufficient movement and/or filtration. This means Legionella can develop in portions of the water supply system where water is stagnant, such as clogs, collection basins and storage tanks.

Other factors that contribute to the development of legionella in water pipes are:

- Biofilm: Legionella can settle in the biofilm that can form in water pipes. Biofilm is a thin, protective layer of bacteria and microorganisms that can settle on surfaces of water pipes.

- Water quality: Legionella can develop in water with high levels of organic contaminants, such as sediment and waste products.

- Warm water: Warm water supplies, such as hot water heaters, increase the likelihood of Legionella development.

- Low flow: Legionella bacteria can multiply in parts of the water supply system where water flow is slow, such as in stagnant water or collection basins.

To prevent the development of Legionella in water pipes, it is important to disinfect and filter regularly and monitor water quality.

HOCl as environmentally friendly and effective disinfectant

An excellent method of controlling Legionella pneumophila in water is to use hypochlorous acid (HOCl) as a disinfectant. HOCl is an oxidizing substance that is extremely effective in killing a wide range of bacteria and viruses, including Legionella pneumophila. It is a safe and environmentally friendly option and does not cause byproducts such as trihalomethanes, which can be harmful to health. It is important to determine the proper concentration level of HOCl and treat the water long enough to kill the bacteria. HOCl can be an excellent option for places where chlorine cannot be used, such as drinking water systems for livestock.

On-site generation with the Watter system

The Watter system is an in situ disinfection technology. In situ is Latin for on-site. By producing your disinfectant on site yourself, you thereby eliminate a number of links in the process, by making purchase, storage and transport of the normally hazardous substances unnecessary. A big step forward in sustainability! And because our system, through electrolysis, produces the disinfectant using water and salt as raw materials, the process is more environmentally friendly and sustainable than other disinfection methods.

Pay attention to the application

Biocide legislation

The Netherlands is governed by Biocide legislation, which regulates the authorization and sale of biocides. Biocides are substances used to kill or suppress harmful microorganisms. This includes the agent generated by the Watter system.

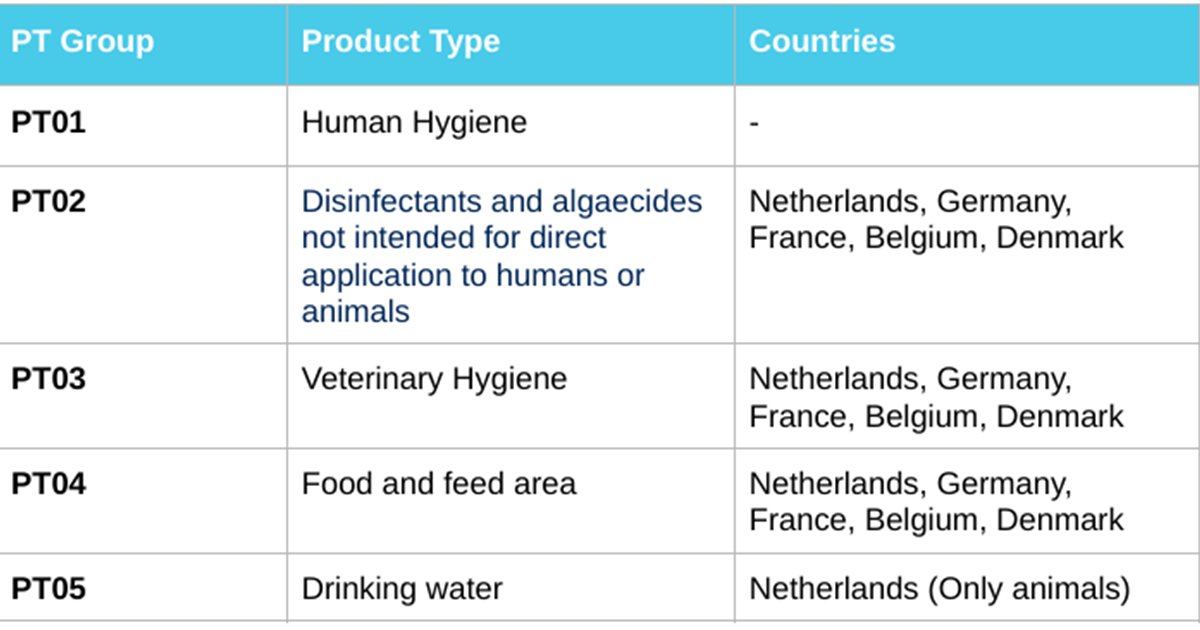

The use of in situ generated disinfectants is only allowed for certain product types (PT). In many cases, legionella control involves disinfection of water intended for human consumption (PT5) and is therefore considerably more strictly regulated than other product types. Currently, the use of the Watter system for human drinking water is not yet permitted. This does not mean that it cannot be done, but the piping system will have to be flushed before the water facilities can be used again. Watter does have an official approval for the disinfection of drinking water for animals in the Netherlands

The Watter system does have approval for other product types under the in situ exception for PT2 and 4. This includes applications such as water for industrial and agricultural use, water for cooling and heating applications and water for recreational purposes.

Below you can find a table in relation to the different types of applications that Watter has the approval for per country. As well as the meaning of the different PT categories